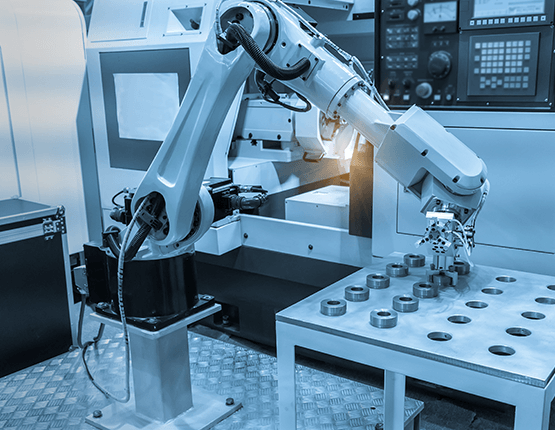

Precision Machining

We offer you the necessary support in finding the optimal solution

- WE MANUFACTURE UNIQUE PIECES

- WE MANUFACTURE SMALL, INTERMEDIATE AND LARGE RANGES

- Design

- Preparation of 2D drawing

- Cutting: Laser, Oxy-fuel and water jet

- Sand Blasting

- Welding

- Plane and cylindrical rectification

- Classic splintering

- CNC splintering

- Contour cutting according to a 3D program

- Lathing

- Adjustment

- Protective and heat treatments (Painting, Browning, Nitriding, Tempering, Anodization)

- Quality control

- 3D measuring and verification

- Mechanical, electrical and pneumatic fitting

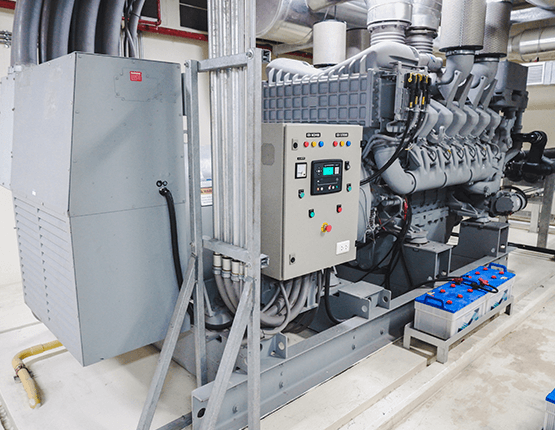

Equipment

The technological equipment of the hall where the mechanical processing takes place:

- 5x Hass VF2 SS, vertical processing center (CNC). 2x 2015 (manufacturing year), 1x 2018, 2x 2019. The tables's dimension is 914mm x 356mm. Working lengths of the axes: 762mm (axis X) x 406 (axis Y) x 508mm (axis Z). 4 machines are with 3 axes. One is with 4 axes.

- 1 x Hass VF3 SS, vertical processing center (CNC), with 4 axes, manufacturing year 2017. The table's dimension is 1219mm x 457mm. Working lengths of the axes: 1016mm (axis X) x 508 (axis Y) x 635mm (axis Z)

- 1 x Victor VTurn-P20 LSB, horizontal lathe (CNC) with bar feeder. This equpment is used mainly for series of parts, with a maximum diameter of 50mm. Manufacturing year - 2016.

- 1 x Heckert CWK 400, vertical processing center (CNC), manufacturing year 1998. This equipment is used mainly for series production.